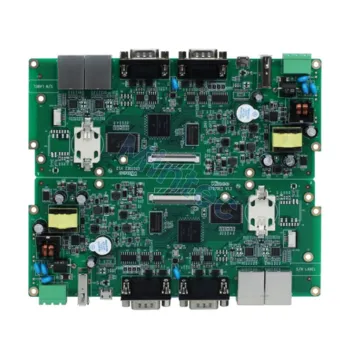

PCB Assembly for Industrial Control Equipment: Ensuring Precision and Reliability

In today's fast-paced industrial landscape, control equipment plays a pivotal role in ensuring seamless operations and maintaining high levels of precision and reliability. One crucial component that enables the functionality of industrial control equipment is the Printed Circuit Board (PCB). In this article, we will explore the significance of PCB assembly in industrial control equipment and the key factors to consider in this critical process. The Role of PCBs in Industrial Control Equipment Industrial control equipment encompasses a wide range of devices used in manufacturing processes, automation, robotics, and other industrial applications. These devices rely on PCBs to provide the necessary circuitry for controlling processes, monitoring parameters, and ensuring safety. PCBs act as the central nervous system of industrial control equipment, facilitating communication between various components and sensors. Precision and Reliability Precision and reliability are paramount in...